Home PageAbout MindatThe Mindat ManualHistory of MindatCopyright StatusWho We AreContact UsAdvertise on Mindat

Donate to MindatCorporate SponsorshipSponsor a PageSponsored PagesMindat AdvertisersAdvertise on Mindat

Learning CenterWhat is a mineral?The most common minerals on earthInformation for EducatorsMindat ArticlesThe ElementsThe Rock H. Currier Digital LibraryGeologic Time

Minerals by PropertiesMinerals by ChemistryAdvanced Locality SearchRandom MineralRandom LocalitySearch by minIDLocalities Near MeSearch ArticlesSearch GlossaryMore Search Options

The Mindat ManualAdd a New PhotoRate PhotosLocality Edit ReportCoordinate Completion ReportAdd Glossary Item

Mining CompaniesStatisticsUsersMineral MuseumsClubs & OrganizationsMineral Shows & EventsThe Mindat DirectoryDevice SettingsThe Mineral Quiz

Photo SearchPhoto GalleriesSearch by ColorNew Photos TodayNew Photos YesterdayMembers' Photo GalleriesPast Photo of the Day GalleryPhotography

╳Discussions

💬 Home🔎 Search📅 LatestGroups

EducationOpen discussion area.Fakes & FraudsOpen discussion area.Field CollectingOpen discussion area.FossilsOpen discussion area.Gems and GemologyOpen discussion area.GeneralOpen discussion area.How to ContributeOpen discussion area.Identity HelpOpen discussion area.Improving Mindat.orgOpen discussion area.LocalitiesOpen discussion area.Lost and Stolen SpecimensOpen discussion area.MarketplaceOpen discussion area.MeteoritesOpen discussion area.Mindat ProductsOpen discussion area.Mineral ExchangesOpen discussion area.Mineral PhotographyOpen discussion area.Mineral ShowsOpen discussion area.Mineralogical ClassificationOpen discussion area.Mineralogy CourseOpen discussion area.MineralsOpen discussion area.Minerals and MuseumsOpen discussion area.PhotosOpen discussion area.Techniques for CollectorsOpen discussion area.The Rock H. Currier Digital LibraryOpen discussion area.UV MineralsOpen discussion area.Recent Images in Discussions

Techniques for CollectorsCutting On a Budget... a SMALL Budget...

12th Jun 2016 19:04 UTCJonelle DeFelice

Yesterday my boyfriend and I went to Harbor Freight to pick up a cheap tool or two. I suddenly thought about looking for some sort of affordable saw blade up to cutting rock, tile, brick, etc. I found a pair of 2 hacksaw blades that supposedly cut such things. I am not sure if they are diamond or not. I figured for $5, if they didn't work, it wouldn't be a huge loss.

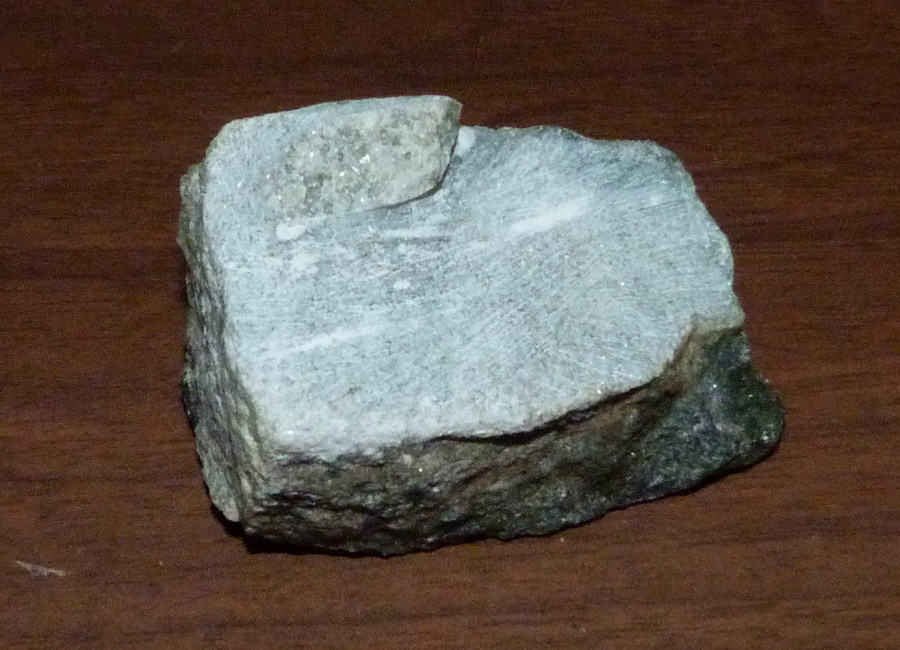

My father dug up an antique hack saw that wasn't being used, and I installed the blade. I chose one rock to experiment on, and went outside onto the porch. All I did was hold the rock against a chair and started to saw. Good thing it is windy today, because there was stone dust everywhere! Attached are photos of my progress in a couple of minutes.

I will have to try actually holding the rock in a vise (without damaging the minerals I want to save) and actually saw correctly.

I am wondering if I should be using water as I saw? Does it matter with a low-speed approach such as mine?

Being a beginner, this is probably only a big deal to me... but I wanted to share my experience anyway. I will let you all know if I get all the way through the rock later!

12th Jun 2016 19:26 UTCBob Harman

12th Jun 2016 19:41 UTCJonelle DeFelice

This particular sample seems to have no "fault lines", which is why it was giving my chisel such trouble in the first place. I am not totally sure what the stone is, I think dolomite marble (from the Chelmsford MA lime quarry). I may try your chisel idea, but I really want to see if I can saw through the whole thing. I've been wondering for so long if I can do it!

:-)

12th Jun 2016 21:19 UTCJonelle DeFelice

A) with softer material

B) with a better vice

C) for someone with a better vice in a room with air conditioning and not a basement!

D) for someone with more patience

E) for someone with more stamina

A mechanical technique would be far FAR better... But I may try again and see what happens.

12th Jun 2016 21:26 UTCDoug Schonewald

I found out early on that nothing was really comparable and I spent twice what I paid for my first tile saw experimenting with this and that. I still have the same saw I bought years ago and am only on my 2nd granite blade and I have made many hundreds of cuts on agate, jasper, and nephrite jade.

My 2-cents

Doug

12th Jun 2016 21:37 UTCJonelle DeFelice

12th Jun 2016 21:53 UTCDoug Schonewald

If I have lapidary material that is large I put it aside and when I have enough I rent a large brick saw and cut it all then take the brick saw back. These days I don't do any lapidary work and use the tile saw strickly to trim for mineral specimens.

12th Jun 2016 21:58 UTCJonelle DeFelice

Stihl Concrete Saw

Now THAT would be fun! ;-)

OR: https://tse2.mm.bing.net/th?id=OIP.Mab0ae3a62cdb09f46a28d42d3f9549b0o0&pid=15.1 ;-)

I actually see a $25 Harbor Freight tile cutter on Craig's List, but when I looked up the specs for it new, it only cuts up to 1".

12th Jun 2016 22:19 UTCDoug Schonewald

http://www.harborfreight.com/7-inch-portable-wet-cutting-tile-saw-40315.html

don't worry about the tilt table it is useless in my mind. I got this at a tag sale for $10 and it is the one I am still using.

13th Jun 2016 02:57 UTCDana Morong

I had a little post a little while ago in this section on 12/20/2015 (a few pages back) "Cutting Excess Matrix with Angle Grinder" and that was a happy experience (even happier when I rigged up some safety stuff, like a clamp made of 2x4 wood and threaded rods, & nuts, to hold the specimen). So it is nice when others contribute also.

25th Aug 2016 19:44 UTCAdam Berluti

Using the hack saw it way too hard and time consuming, I know from experience trying to cut a quartz geode...

26th Aug 2016 14:51 UTCSam Linton

The saw blade (bought from Lowe's) is pretty good and has lasted a long time even cutting quartz. Only bad thing is that the yellow paint like to wear off onto the piece if you are not careful and try to cut too much off. Its not meant for deep cuts, so that is understandable.

Harbor Freight is where I got all my equipment... be on the lookout for deals as they usually offer coupons and discounts. Shipping can even be reduced with discounts. My set up was under $300 to include saw, blade, grinder, buffer, and misc sand paper and buffing grit. It is worth it considering the pieces I now have that I would not have had with out that equipment.

26th Aug 2016 21:33 UTCJonelle DeFelice

Also, another drawback to the hacksaw wire... it is about 1/8" thick. So you need to factor this in when planning a cut.

26th Aug 2016 21:49 UTCBob Harman

28th Aug 2016 21:02 UTCJonelle DeFelice

30th Aug 2016 20:41 UTCDana Morong

Mindat.org is an outreach project of the Hudson Institute of Mineralogy, a 501(c)(3) not-for-profit organization.

Copyright © mindat.org and the Hudson Institute of Mineralogy 1993-2024, except where stated. Most political location boundaries are © OpenStreetMap contributors. Mindat.org relies on the contributions of thousands of members and supporters. Founded in 2000 by Jolyon Ralph.

Privacy Policy - Terms & Conditions - Contact Us / DMCA issues - Report a bug/vulnerability Current server date and time: April 20, 2024 00:28:41

Copyright © mindat.org and the Hudson Institute of Mineralogy 1993-2024, except where stated. Most political location boundaries are © OpenStreetMap contributors. Mindat.org relies on the contributions of thousands of members and supporters. Founded in 2000 by Jolyon Ralph.

Privacy Policy - Terms & Conditions - Contact Us / DMCA issues - Report a bug/vulnerability Current server date and time: April 20, 2024 00:28:41